Necessary to electrically ground

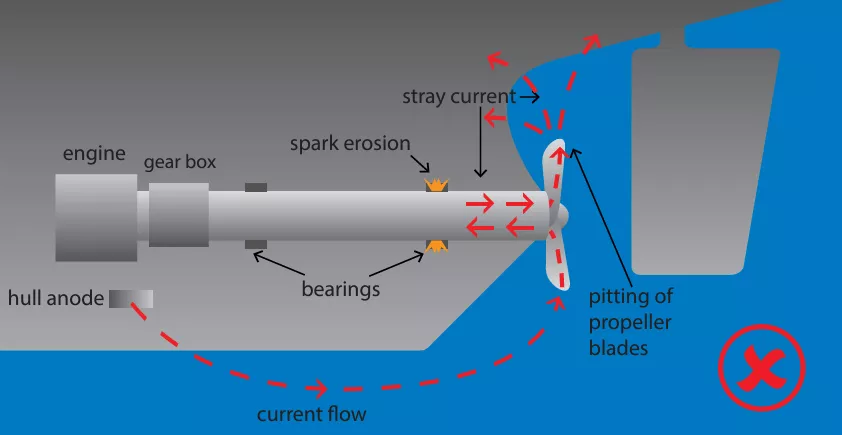

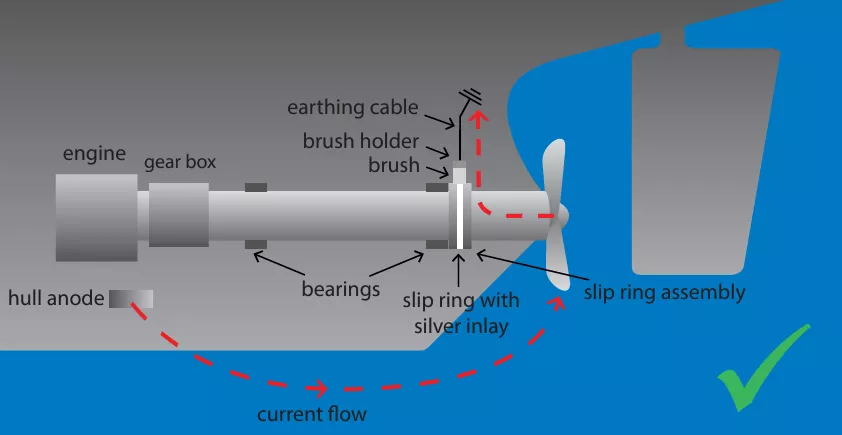

It is absolutely necessary to electrically ground the ship's propeller shaft to the hull. Because a rotating propeller generates a voltage potential difference between the shaft and the hull, which in time will case damage to the propeller and the bearings. This voltage potential difference is generated because of the lubricating oil films in bearings and non-metallic materials resulting in electrical isolation of the shaft. The heavy electrical current flowing through the bearings and gearbox to the hull will be minimized by our earthing system, in order to prevent corrosion and damage.

How our Propeller Shaft Earthing System works

The Althen PSE system is engineered with precision to direct any stray electrical currents from the rotating propeller shaft back to the ship's hull. At the heart of this system lies a durable copper slipring with a solid silver inlay, which connects to the shaft via stainless steel clamping bands and dedicated connectors. A brush holder containing two high-quality silver/graphite brushes, positioned to run smoothly over the slipring, ensures optimal electrical continuity. This secure connection effectively grounds the propeller shaft, drastically reducing spark erosion and significantly extending the life of the propulsion machinery, ultimately leading to a lower total cost of ownership.

SE2400081 Earthing brush

- Brushes for propeller shaft system - 80% silver and 20% graphite.

- Must be mounted on a Ø12mm rod

SE2100045-2 Earthing Brushholder

- Brushholder is part of Propeller Shaft Earthing System

- Double balancing

- Pressure setting

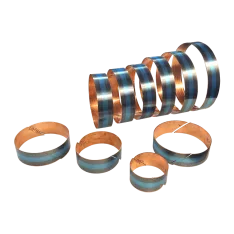

SE2100045-1 Silver/Copper Strip for Slipring

- Copper slipring with solid silver inlay

- Shaft diameters Ø100 - Ø1400 mm

Monitoring for propeller shaft protection

Beyond its primary protective function, the Althen PSE system offers an advanced monitoring option. Installed in the engine room, this monitoring unit allows operators to track the potential difference between the propeller shaft and the hull in real time. A single insulated brush holder, equipped with a silver/graphite brush and an analog mV-meter, operates independently without external power, ensuring seamless functionality.

Reading potential issues with the mV-meter

If the shaft earthing system is functioning correctly, the mV-meter will read below 50mV. However, a reading above 50mV indicates a potential issue, such as dirt buildup, wear, or incorrect installation, and prompts immediate inspection. For added security, an optional 4-20mA converter can be installed, which triggers an alarm on the bridge if the potential difference exceeds safe levels.

8047A Propeller Shaft Earthing Set

- Complete monitoring set

- Indispensable for seagoing ships

- Directs electrical current that flows through the propeller shaft to the hull of the ship

8047A-8047M Propeller Shaft Earthing and Monitoring System

- Complete system

- Propeller shaft earthing set

- Cabin monitoring system included

Key benefits of the PSE system

With Althen's PSE system, ship operators can feel confident in the reliability and longevity of their vessels. Key benefits of this system include:

-

Preventing spark erosion in bearings

-

Reducing cavitation on propeller blades

-

Lowering maintenance costs

-

Avoiding costly damage to propulsion machinery

Ensure your vessel’s reliability

Protect your vessel and lower maintenance costs with the advanced Althen Propeller Shaft Earthing System. Don’t let spark erosion and costly repairs hold you back – contact us today to learn more about how Althen PSE can keep your ship sailing smoothly. Reach out now to request a consultation or find out more about our complete earthing solutions for marine vessels.